The Role of 2D Bags in Bioprocessing: Enhancing Efficiency and Reliability

In the evolving landscape of bioprocessing, the quest for innovative, efficient, and reliable solutions never ceases. One such solution that has gained significant traction is the use of single-use 2D Bags.

These flexible containers have revolutionized the way bioprocesses are managed, offering numerous benefits that contribute to the overall efficiency and quality of bioproducts. Let's delve into why 2D Bags are so important in bioprocessing, with a special focus on the offerings from Venair.

1. Scalability: Adapting to Diverse Production Needs

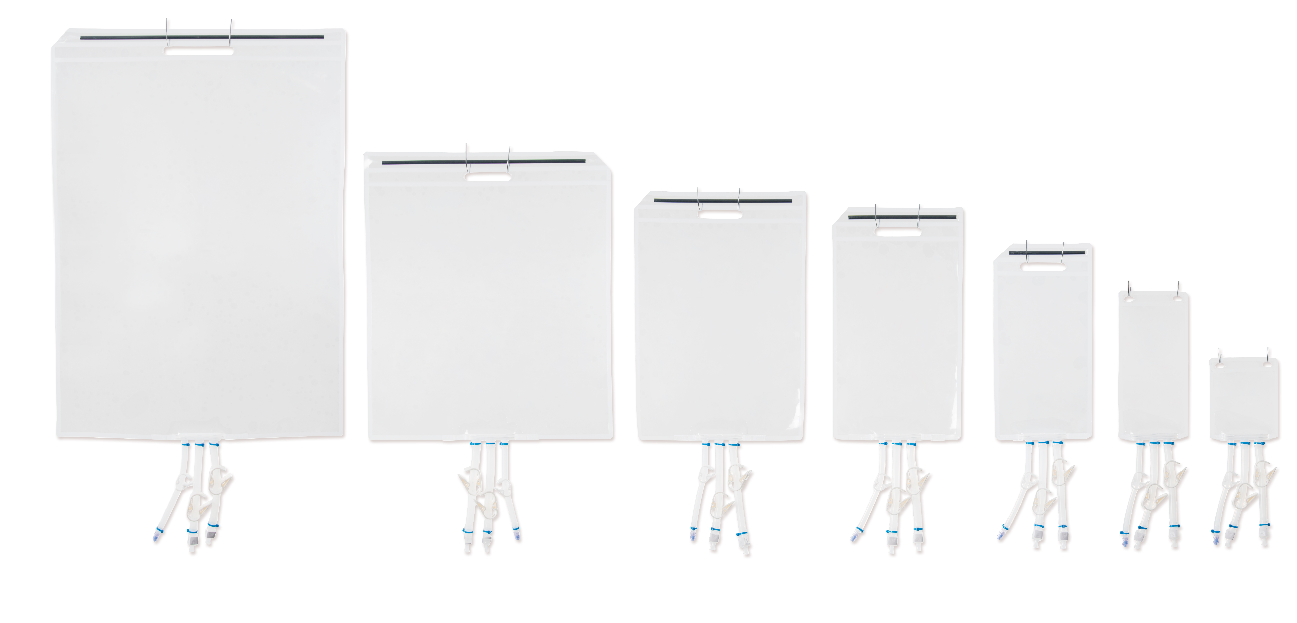

One of the most significant advantages of 2D Bags is their scalability. Bioprocessing requirements can vary widely, from small-scale laboratory experiments to large-scale industrial production. 2D Bags come in a variety of sizes, making it easy to scale up or down without major modifications to the existing process. This flexibility ensures that bioprocessing can be efficiently adapted to meet changing production demands, whether it’s for pilot studies or full-scale manufacturing.

2. Sterility and Contamination Control: Ensuring Product Integrity

Maintaining a sterile environment is paramount in bioprocessing to ensure the quality and safety of the final product. 2D Bags are typically pre-sterilized and designed for single use. This disposability significantly reduces the risk of contamination that can arise from repeated use and cleaning of traditional equipment. By using 2D Bags, bioprocessors can maintain high standards of sterility, thus protecting the integrity of their bioproducts.

3. Cost Efficiency: Reducing Operational Expenses

The use of disposable 2D Bags translates to significant cost savings. Traditional bioprocessing equipment, such as stainless-steel tanks, requires extensive cleaning and sterilization between uses, which is both time-consuming and costly. In contrast, 2D Bags eliminate the need for these labor-intensive cleaning processes. By reducing the time and resources spent on cleaning and maintenance, bioprocessors can achieve more cost-effective operations.

4. Simplified Logistics: Ease of Handling and Storage

2D Bags are lightweight and easy to handle compared to bulky stainless-steel containers. This simplicity extends to their storage and transportation, as they take up less space and require less energy to move. The logistical advantages of 2D Bags make them an attractive option for bioprocessing facilities looking to streamline their operations

5. Flexibility and Customization: Tailored to Specific Needs

Bioprocessing often involves a wide range of requirements depending on the specific application. These bags can be customized to meet diverse needs, whether it’s adjusting the size, shape, or material properties to suit bioprocessing conditions.

At Venair, we offer a wide range of customizable polyethylene 2D Bags designed to cater to specific bioprocessing needs, ensuring optimal performance and reliability.

6. Environmental Considerations: Supporting Sustainable Practices

The reduced need for water and chemicals for cleaning, coupled with lower energy consumption for sterilization, means that single use bags can contribute to a smaller environmental footprint. Additionally, advancements in materials science are leading to more recyclable and biodegradable options, further enhancing the sustainability of these disposable solutions.

Conclusion

The importance of single use bags in bioprocessing cannot be overstated. Their scalability, sterility, cost efficiency, logistical simplicity, flexibility, and environmental benefits make them a vital component in modern bioprocessing operations.

Whether you’re a researcher in a small lab or a manager in a large manufacturing facility, disposable 2D Bags offer practical solutions to enhance your bioprocessing workflow.