Bioprocess Automation and Robotics: Pioneering the Future of Biomanufacturing

The biopharmaceutical industry has reached a pivotal moment as automation and robotics transform the efficiency, precision, and scalability of bioprocessing. These technologies are no longer confined to experimental use—they are rapidly becoming essential tools for modern manufacturing.

The industry is leveraging these advancements to address the increasing demand for biologics, streamline production, and maintain rigorous quality standards.

Revolutionizing Cleanroom Operations

Cleanrooms, essential for maintaining sterility during production with platinum cured silicone tubing, are seeing dramatic improvements through the integration of robotic systems. Traditionally reliant on manual labour, these controlled environments are now benefiting from automation that reduces human intervention and the associated risks of contamination.

- Precision and Consistency: Robotic arms can handle aseptic filling, capping, and material transfers with unmatched accuracy, ensuring batch-to-batch uniformity.

- Increased Productivity: Unlike human operators, robotic systems can work continuously, accelerating throughput while maintaining compliance with regulatory standards.

In vaccine production, for instance, robots now perform repetitive, high-stakes tasks such as vial filling, a critical operation where sterility is paramount.

Automated Media Preparation and Monitoring

Preparation of culture media, a cornerstone of upstream bioprocessing, has been transformed by automation. Advanced systems now precisely formulate and deliver media while simultaneously monitoring critical parameters such as pH, dissolved oxygen, and nutrient concentrations in real-time.

This real-time feedback loop allows manufacturers to:

- Optimize Growth Conditions: Automated adjustments to media composition enhance cell health and productivity.

- Ensure Reproducibility: Reducing human error results in consistent production outcomes, which is critical for meeting stringent quality control benchmarks.

For example, automated systems can dynamically adjust nutrient feed rates in perfusion bioreactors to sustain optimal cell density during continuous manufacturing processes.

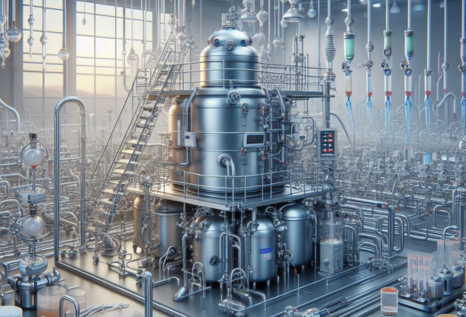

The Rise of Fully Automated Bioreactors

Bioreactors, the heart of bioprocessing operations, are becoming increasingly autonomous. These systems are designed to handle everything from parameter monitoring to self-sterilization, significantly reducing downtime and operational complexity.

- Enhanced Scalability: Modular and automated bioreactor setups allow for rapid scaling to meet market demands, whether for monoclonal antibodies or emerging mRNA-based therapeutics.

- Streamlined Operations: Built-in Cleaning-In-Place (CIP) and Sterilization-In-Place (SIP) capabilities minimize the need for manual maintenance, ensuring uninterrupted operations.

Digital control systems further enhance these bioreactors by providing actionable insights into process performance and enabling predictive maintenance through AI-driven analytics.

Challenges and the Road Ahead

Despite these advancements, the adoption of automation and robotics is not without challenges. High upfront costs, the complexity of integrating legacy systems, and the need for specialized expertise can pose hurdles for biomanufacturers. Additionally, cybersecurity concerns arise as facilities become more digitally interconnected.

However, ongoing collaboration between industry stakeholders, technology providers, and regulatory bodies is addressing these challenges. Regulators like the FDA and EMA are increasingly issuing guidelines that support digitalization and automation in biomanufacturing, fostering confidence in adopting these innovations.

Conclusion

The integration of automation and robotics is revolutionizing bioprocessing by driving efficiency, ensuring product quality, and enabling scalability. As these technologies continue to evolve, their potential to further transform the industry is immense. In this era of accelerated innovation, the successful adoption of automation and robotics will be a defining factor for companies aiming to lead in the competitive landscape of biologics manufacturing.

By embracing these cutting-edge tools, the biopharmaceutical industry is paving the way for a future where precision, speed, and quality are the hallmarks of biomanufacturing.