Safety and Efficiency of Electric Vehicle Batteries: The Role of Critical Connectors

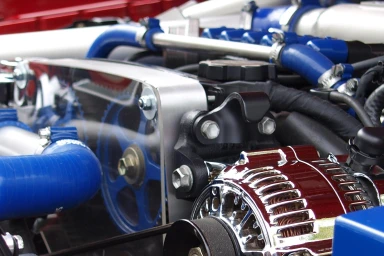

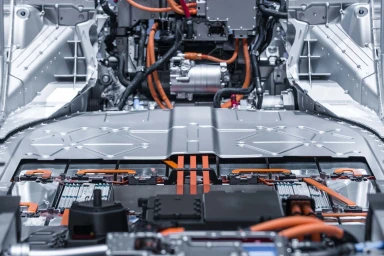

As the automotive industry races towards a sustainable future, electric vehicles (EVs) are at the forefront of this revolution. At the heart of these cutting-edge machines lies a crucial component known as the Battery Thermal Management System (BTMS). The BTMS, comprising a complex network of hoses and pipes, is responsible for regulating the temperature of lithium-ion batteries, ensuring their optimal performance and safety.

In this article, we explore the significance of these critical connectors within the BTMS, with a focus on the pioneering efforts of Venair, a renowned manufacturer of flexible hoses serving high-performance industries.

The Importance of Battery Thermal Management Systems

In the world of EVs, the performance and safety of lithium-ion batteries are paramount. The BTMS plays a pivotal role in this regard, as it is designed to maintain the batteries within their optimal temperature range. Proper thermal management is essential for several reasons:

Enhancing Battery Performance

Maintaining the ideal temperature range ensures that lithium-ion batteries operate at peak efficiency, leading to extended lifespan and enhanced performance.

Ensuring Safety

Effective temperature control mitigates the risk of thermal runaway, which can result in fires or explosions—a critical concern for the EV industry.

Maximizing Energy Efficiency

A well-regulated temperature not only ensures the safety of the batteries but also preserves the overall energy efficiency of the vehicle. Overheating results in energy loss and decreased efficiency.

Critical Connectors in Battery Thermal Management Systems

The intricate network of hoses and pipes that constitute the BTMS connectors is where Venair's expertise truly shines. This Spanish manufacturer, with decades of experience serving high-performance industries such as automotive, aerospace, and fuel cells, has become a leading player in the market. Their commitment to improving the performance of thermal management systems has never been more critical than in the context of EVs.

Addressing Flammability Concerns

Flammability is a grave concern when dealing with lithium-ion batteries. To minimize the risk of fires in EVs, it is essential to employ connectors that meet rigorous safety standards. Venair's dedication to safety is evident through their use of flexible pipes that meet UL-94 certification standards, with an aim for a minimum V0 rating. This certification ensures that the materials used in these connectors are flame-resistant, reducing the risk of fire hazards in BTMS.

Tackling Leakage Issues

While achieving a 0% leakage rate may be challenging in practice, it is crucial to minimize leakage within the BTMS. Leakage can lead to various issues, including short circuits, coolant loss, and contamination of surrounding systems. Venair's flexible hoses are designed to maintain an exceptionally low leakage rate, contributing to the overall safety and efficiency of BTMS.

The Unique Challenges of EV Batteries

EV batteries have specific operating ranges critical for their performance and lifespan. They are designed to operate within an ambient temperature range of 68°F to 77°F (20°C to 25°C). However, batteries can experience extreme temperatures during operation and charging:

During operation, they can withstand temperatures between -22°F and 140°F (-30°C and 50°C).

During recharging, they can tolerate temperatures between 32°F and 122°F (0°C and 50°C).

Effective thermal management is crucial to keep the batteries within these ranges. High temperatures, especially between 158°F and 212°F (70°C and 100°C), can trigger thermal runaway, a catastrophic chain reaction that destroys the battery pack.

Challenges in Thermal Management

The most common challenges in thermal management for EV batteries include:

Leaks: Liquid cooling systems, common in EVs, can develop leaks as the battery ages, posing a significant risk to performance and safety. Venair's connectors are designed to minimize this risk.

Corrosion: Liquid cooling systems can experience corrosion as the coolant ages, necessitating regular maintenance to replace the cooling liquid.

Clogging: Liquid cooling systems have many small channels through which coolant flows, posing a risk of clogging.

Climate Variability: Batteries must withstand diverse climate conditions, from extreme heat to bitter cold, requiring active thermal management even when the vehicle is not in use.

Aging: As batteries age, they generate more heat, demanding robust thermal management systems that can handle these tougher conditions.

Conclusion

In the transition to a sustainable and electrified automotive future, the role of Battery Thermal Management Systems cannot be overstated. The connectors within these systems, exemplified by Venair's innovative flexible hoses, play a vital role in ensuring the safety, efficiency, and longevity of electric vehicle batteries. With the unique challenges posed by EVs, including flammability, leakage, and temperature regulation, companies like Venair are essential partners in driving the industry towards a cleaner and safer tomorrow.