Ensuring Minimal Leakage in Silicone Hoses: A Comprehensive Guide

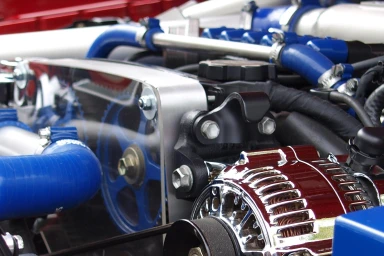

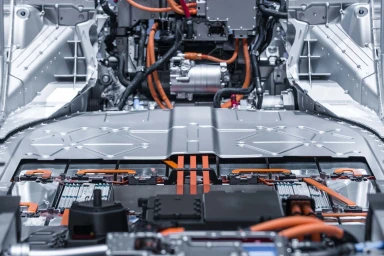

Silicone hoses are widely used in various industries for their durability, flexibility, and resistance to extreme temperatures. However, ensuring the lowest possible leakage in silicone hoses is crucial to maintain efficient and reliable systems. In this article, we'll explore the common sources of leakage in silicone hoses and provide practical solutions to mitigate them.

Identifying Critical Leakage Points

Leakage in silicone hoses typically occurs at specific points within the system. It's essential to identify and address these critical areas to minimize the risk of leaks. The main culprits for leakage are as follows:

Connection Points

Leakage often arises from the connection points in silicone hose systems. Excessive connection points can significantly increase the likelihood of leaks. To tackle this issue, consider the following measures:

Reduce the Number of Connections: Minimize the use of multiple connections by opting for custom-shaped hoses when possible. While using standard hose sections may be convenient, creating a "Frankenstein" assembly from various pieces introduces unnecessary risk. Custom shapes can help reduce the number of potential leakage points.

Use Proper Clamps: Ensure that the clamps used are suitable for the hose material and outer diameter. Proper clamps provide a secure, leak-resistant connection. Additionally, they should offer consistent tension along the perimeter of the hose.

Check Connection Spikes: Examine the connection points for spikes, taking into account the outer diameter and convolution. Ensuring that the connection points are well-suited to the hoses can help decrease leakage risks.

Quality of Hoses

The quality of silicone hoses plays a pivotal role in preventing leakage. High-quality hoses are essential for maintaining leak-free systems. Consider the following factors:

Internal Holes: Some hoses may have internal holes that can lead to leaks. Reducing the number of these holes is crucial to prevent leakage throughout the hose's construction. Always opt for hoses with minimal internal holes for better reliability.

Material Quality: Invest in high-quality silicone hoses known for their durability and resistance to pressure and temperature variations. Lower-quality hoses with imperfections can lead to leakage and system failures.

Cracks and Cuts

Cracks and cuts in silicone hoses are common issues that can result in leaks, particularly under high pressure. Take precautions to minimize the risk:

Handle Hoses Carefully: Be cautious when handling silicone hoses, especially around sharp objects like box cutters. Cuts in the hoses may not be immediately visible, but they can lead to leaks and eventual hose bursts when exposed to increased pressure.

Conclusion

Preventing leakage in silicone hoses is essential for the efficient operation of various systems. By focusing on reducing connection points, using appropriate clamps, selecting high-quality hoses, and handling them with care, you can ensure the lowest possible leakage and maintain the integrity of your silicone hose systems. Prioritizing these measures will lead to reliable and leak-free operations, ensuring the smooth functioning of your machinery and processes.