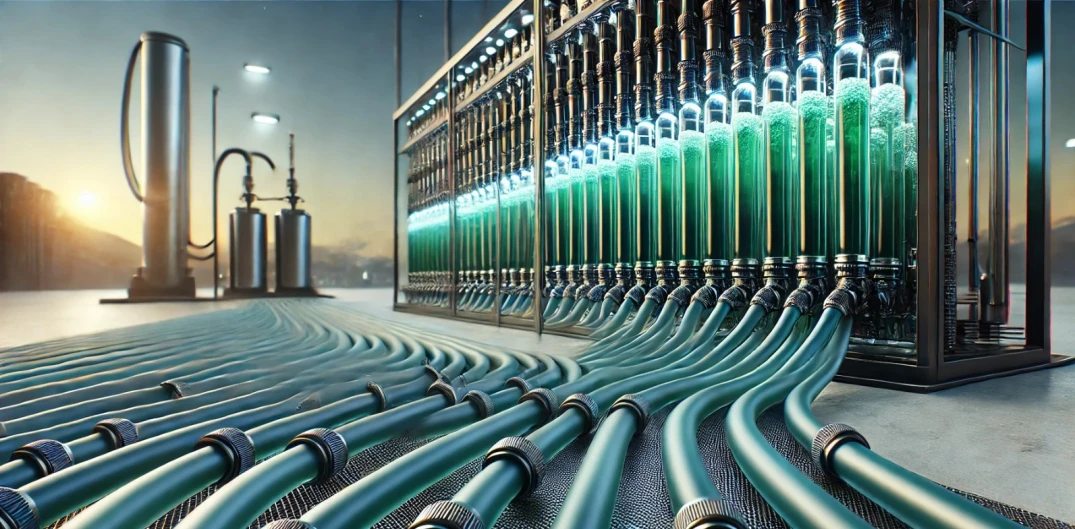

Flexible hoses for DI Water inlet in PEM electrolyzers

As the world accelerates towards sustainable energy solutions, Proton Exchange Membrane (PEM) electrolyzers play a pivotal role in harnessing clean hydrogen for industrial electrification. At the heart of this transformative process lies the use of deionized water, a crucial element introduced into PEM electrolyzers.

In this article, we explore how Venair, leveraging its profound expertise in the biopharmaceutical and biotech industries, has become the foremost provider of high-purity flexible tubing for the entry of deionized water into PEM electrolyzers globally.

The Essence of Deionized Water in PEM Electrolyzers

Deionized water serves as the canvas for the energy alchemy within PEM electrolyzers. It undergoes electrical disassociation, yielding the coveted duo of oxygen and hydrogen. This hydrogen, a clean and versatile energy carrier, holds the key to transforming industries into more sustainable and eco-friendly entities.

Venair's Specialization: High-Purity Flexible Tubing

Venair, with a rich background in producing high-purity products for the stringent biopharmaceutical sector, has seamlessly transitioned its expertise into the realm of green hydrogen production. The company stands out as the primary supplier of flexible tubes designed explicitly for the entry of deionized water into PEM electrolyzers on a global scale.

Optimized Materials for Peak Proton Exchange Membrane Efficiency

Venair's commitment to excellence is evident in its optimization of tubing materials for maximum Proton Exchange Membrane (PEM) efficiency. Extensive reports and tests are available, showcasing how these materials are meticulously engineered to minimize contaminants harmful to the membrane. The reduction of conductivity in materials, coupled with minimizing the release of ions into the conducted medium, ensures a seamless and efficient PEM process.

Reducing Contaminants: A Critical Imperative

In the intricate dance of PEM electrolysis, the need to minimize contaminants takes center stage. Venair's high-purity flexible tubing is designed with a focus on mitigating the introduction of harmful substances that could compromise the integrity of the membrane. This meticulous approach aligns with the company's commitment to advancing green innovation and sustainable hydrogen production.

Venair's Unparalleled Experience and Global Impact

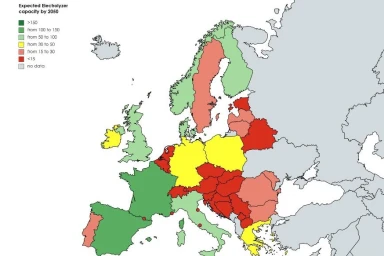

With over four decades of expertise in elastomers, Venair is today the leading global supplier of flexible tubes for PEM Fuel Cells and electrolyzers. Serving major Original Equipment Manufacturers (OEMs) across Europe, North America, Asia, and Oceania, Venair seamlessly integrates knowledge from the automotive, pharmaceutical, and biotech industries. This fusion of experience positions Venair as the trusted solution provider for Proton Exchange Membrane technology.

Conclusion

In the relentless pursuit of sustainable energy solutions, Venair emerges as a beacon of innovation, providing unparalleled high-purity flexible tubing for PEM electrolyzers. As industries worldwide embrace the green potential of hydrogen, Venair's commitment to optimizing materials and reducing contaminants underscores its role as a key player in shaping the future of clean energy. With a legacy of expertise and a global impact, Venair stands as a testament to the seamless fusion of knowledge, experience, and commitment to sustainability.