Hose Connections: Enhancing Tightness in Cooling Systems

In most cooling systems and applications where a radiator is required it is normally accepted the tightness all the hoses to the nipples or junctions with simple hose clamps.

These clamps are of different qualities and finishing like the ones with embedded ends, so we avoid cuts in front of excessive tight them, or the ones of constant tension or torque which avoid to excess the recommended tight.

This is possible because these systems don’t work at high pressure and due it’s low cost compared to using crimped fittings.

Alternatives to Clamps: Crimped Fittings and their Comparative Cost

Nowadays it is more common for some OEMs to seek to increase the reliability and performance of their equipment, looking for complete sealed solutions that can withstand higher pressures due to increased temperatures of their engines or the irradiation that needs to be supported.

Common Hydraulic Fittings: GAS BSP, NPT, Flanges, and Others in Industrial Applications

There are multiple types of fittings manufactured with different materials that are commonly used for industrial applications. Most of them are used in hydraulic applications such as GAS BSP, NPT, Flange and so on.

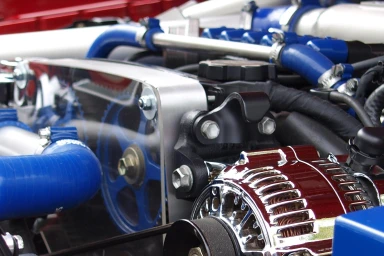

Venair's Connection Program: Development in Stainless Steel and Certifications of Strength

At Venair we have developed our connections program mainly in Stainless Steel 316L or 304, Cooper and even Aluminium, adapting them to perfectly fit in any of our hoses.

When required, we can provide the correspondent hydrostatic pressure test to certify the product working resistance as well as the certification 3.1B regarding the material composition used to manufacture the connections.

Custom made shape with crimped Flanges in Stainless Steel and moulded silicone Flange.

Standard Silicone Hose SAEJ20 R1 with crimped fittings. Possibility of crimping R2 and R3 hoses.