Venair’s Innovative Material for KOH Compatibility in AEM and Alkaline Electrolyzers

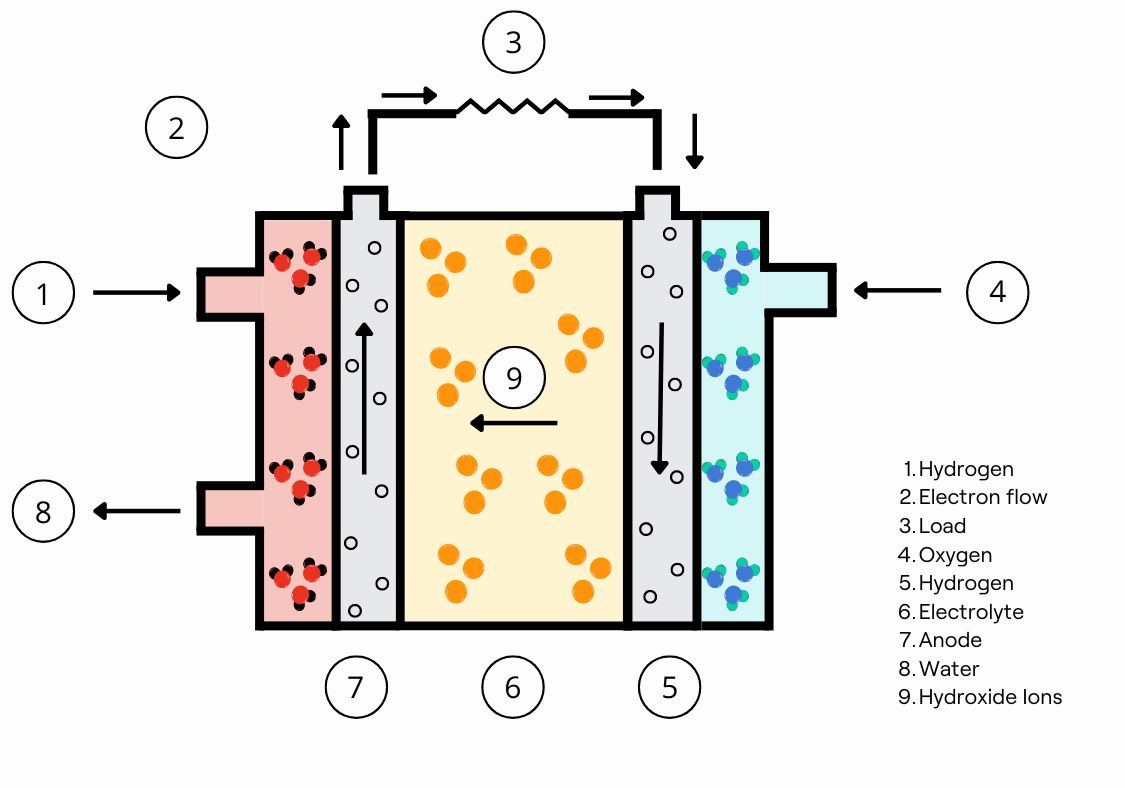

Venair, a global leader in flexible hose manufacturing, has recently developed an advanced material specifically designed for the production of straight or shaped hoses, including manifolds and highly complex pieces. This new material demonstrates exceptional chemical compatibility with Potassium Hydroxide (KOH), making it ideal for use in AEM electrolyzers, alkaline electrolyzers, and alkaline fuel cells (AFCs).

KOH, known for its aggressive nature, can quickly degrade many elastomers, including FKM (fluoroelastomer), which typically boasts strong chemical resistance. However, Venair’s material shows remarkable resistance to KOH, enabling it to safely transfer or maintain contact with the substance without compromising performance. This breakthrough is particularly important in the field of AEM fuel cells and alkaline fuel cells, where the compatibility of materials with KOH is critical for long-term functionality.

Proven Success in PEM Fuel Cells and Electrolyzers

This new material is based on Venair’s existing innovation for PEM fuel cells and PEM electrolyzers, which have gained a reputation for high efficiency and durability. The material was specifically engineered to offer:

- Low permeability (considering it is an elastomer), reducing the loss of gases and ensuring optimal system performance.

- Minimal release of contaminants, which is crucial in preventing damage to the PEM membrane or the catalyst.

By ensuring these characteristics, Venair has become a trusted supplier to major developers of PEM electrolyzers and PEM fuel cells. The company's material continues to demonstrate its superior performance, contributing to enhanced energy efficiency and longevity in fuel cell and electrolyzer applications.

AEM and AFC Developers Adopting Venair’s Solution

As of now, several developers of AEM electrolyzers and alkaline fuel cells have begun integrating Venair’s new material into their systems due to its unparalleled chemical compatibility with KOH. This is a significant development, as most elastomers struggle to withstand prolonged exposure to KOH without degradation.

The material’s ability to resist chemical wear from KOH opens new possibilities in the design and operation of AEM and alkaline fuel cells, providing developers with a durable solution that can handle aggressive chemicals over extended periods. This is a critical advantage in industries seeking more reliable and efficient energy systems.

VENA® PEM CELL FLAME: Safety and Compliance

Venair manufactures these hoses using the VENA® PEM CELL FLAME construction, a UL-94 certified material that meets the highest flame retardancy standards, with a V0 rating for flammability. This certification ensures that the hoses meet stringent safety requirements, providing added protection in high-temperature environments and reducing the risk of fire.

Another key feature of the VENA® PEM CELL FLAME material is that it contains no PFAs (Per- and Polyfluoroalkyl Substances). This is a critical benefit, as PFAs are set to be banned across Europe and North America in the coming years, with other regions like Asia and Oceania likely to follow suit. Unlike FKM, which often contains PFAs, Venair’s material offers a future-proof solution for industries transitioning away from PFAs due to regulatory changes.

Venair: A Global Leader in PEM Fuel Cell and Electrolyzer Solutions

Venair is a world leader in the design and manufacture of flexible hoses for various industries, with a special focus on PEM fuel cells and PEM electrolyzers. With over 30 years of experience and a strong commitment to innovation, the company provides high-performance solutions that meet the rigorous demands of fuel cell technology.

Venair’s products are trusted by developers around the globe for their durability, safety, and chemical compatibility. As the demand for cleaner, more efficient energy solutions grows, Venair continues to lead the way in providing the flexible hose solutions needed to power the future.

Conclusion

Venair's latest innovation in flexible hose materials, with its exceptional KOH compatibility, opens up new possibilities for AEM electrolyzers, alkaline fuel cells, and other applications requiring robust chemical resistance. With the VENA® PEM CELL FLAME material, developers can now rely on a product that not only meets the highest safety standards but also anticipates future regulatory changes by eliminating PFAs from its composition.

For those in the energy industry looking to enhance the efficiency and durability of their systems, Venair’s advanced hose materials offer the optimal solution for PEM, AEM, and alkaline fuel cell technologies.