New PEM CELL FLAME: The ultimate R&D material for PEM FC hoses, now UL-94 Flammability certified.

In the dynamic world of cutting-edge industries, innovation is not just a buzzword; it's a necessity. Venair, a pioneering company specializing in flexible hoses and pipes, has been at the forefront of innovation for critical industries since its inception. With a focus on sectors like automotive, aerospace, pharmaceuticals, and biotechnology, Venair has been setting new standards for excellence.

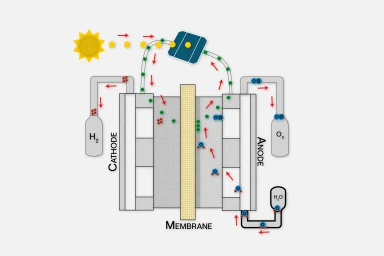

However, one of their most remarkable achievements lies in the realm of Hydrogen PEM (Proton Exchange Membrane) Technologies. This article delves into Venair's journey in this rapidly growing industry and introduces their latest game-changing product upgrade, VENA® PEM CELL.

The Challenge

Developing Specialized Materials Hydrogen PEM Technologies are highly sensitive to a multitude of factors such as contaminants, cleanliness, permeability, and conductivity. To lead in this sector, Venair recognized the need to go beyond using common materials employed in other industries. They embarked on a journey to develop specific materials tailored to meet the stringent requirements of Fuel Cell and electrolyzer manufacturers.

The Breakthrough

VENA® PEM CELL Upgrade Venair's latest product launch marks a significant milestone in their quest for excellence. The VENA® PEM CELL upgrade builds upon the company's already outstanding product, enhancing performance and quality with a focus on materials critical to the industry:

- Permeability: VENA® PEM CELL boasts lower permeability, a crucial factor for efficient Hydrogen conduction.

- Contaminants: This upgraded material reduces the leaching of volatiles, while also addressing the specific types of volatiles that are most critical for Proton Exchange Membrane performance.

- Conductivity: VENA® PEM CELL's formulation ensures very low electrical conductivity, although customization options allow for inner or outer layers to be made conductive if necessary.

- Low Acidification: The material significantly lowers acidification of the medium, a critical factor in maintaining a suitable environment within the Hydrogen loop.

Flammability requirements for hoses in Fuel Cells (UL-94)

Venair's commitment to safety is unwavering. The VENA® PEM CELL upgrade complies with the UL-94 certification, achieving the highest possible V0 rating according to the "Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances testing." This is paramount, as it ensures the utmost safety in systems managing and conducting Hydrogen.

Venair doesn't stop at VENA® PEM CELL. Their entire range of products specialized for Fuel Cells is UL-94 certified to guarantee the lowest flammability rates. This includes VENA® PEM FUEL (FKM), VENA® PEM PURE (high-purity silicone), VENA® PEM COOL (regular silicone), and the aforementioned VENA® PEM CELL.

Industry Trust and Future Prospects

Venair's commitment to excellence is reflected in the trust bestowed upon them by some of the world's most prominent Fuel Cell and Electrolyzer manufacturers. Their objective is clear: to continue expanding in this industry by nurturing research and development while creating new solutions that align with the ever-evolving demands of PEM technologies.

Conclusion

Venair's journey in the realm of Hydrogen PEM Technologies is a testament to their dedication to innovation and excellence. With the introduction of the VENA® PEM CELL upgrade, they have once again proven themselves as pioneers in the field. As the industry evolves, Venair remains poised to lead the way, shaping the future of Hydrogen PEM Technologies with cutting-edge solutions that meet the industry's most critical requirements.

Venair's Hydrogen PEM Technologies Odyssey

Since 2015, Venair has directed its resources and expertise towards the flourishing Hydrogen PEM Technologies sector. Today, they proudly stand as the foremost Tier 1 supplier for some of the industry's biggest OEMs. Their success can be attributed to a steadfast commitment to innovation and a focus on addressing the industry's most critical challenges.