Upstream vs. Downstream Processing in Biomanufacturing

In the dynamic field of biomanufacturing, the two pivotal stages, upstream and downstream processing, orchestrate the intricate symphony of producing biopharmaceuticals and bioproducts. These phases not only play a crucial role but also present various challenges and opportunities. In this comprehensive article, we will delve deeper into the key differences and intricacies of upstream and downstream processing in the bioprocessing industry.

Upstream Processing: Nurturing the Biological Blueprint

Upstream processing serves as the cradle of biomanufacturing, where biological entities like microorganisms or mammalian cells are cultivated and nurtured in a meticulously controlled environment. At its core, this phase revolves around the production of the desired biological product, typically a protein, vaccine, or therapeutic antibody.

-

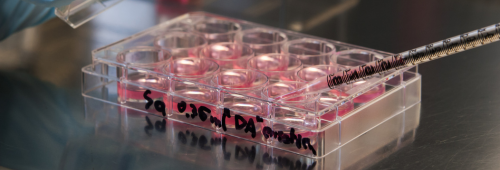

Cell Culture: The heart of upstream processing lies in the cultivation of cells within bioreactors. These bioreactors meticulously control variables like temperature, pH, oxygen levels, and nutrient supply to optimize cell growth and product production.

-

Media Preparation: Nutrient-rich media are the lifeblood of cell culture. These concoctions comprise essential components such as sugars, amino acids, vitamins, and minerals, ensuring the cells have everything they need to flourish.

-

Fermentation: Scaling up cell culture often demands fermentation processes. This involves transitioning from small-scale laboratory settings to industrial bioreactors to maximize product yield.

-

Harvesting: Once the cells reach their zenith of growth and product production, they must be harvested. Techniques like centrifugation and filtration come into play to separate cells from the culture broth.

Downstream Processing: The Art of Refinement

Downstream processing follows the upstream phase, focusing on the purification, isolation, and refinement of the target product from the complex biological mixture brewed in the bioreactor. This phase is the crucible in which raw materials are transformed into a product of the highest purity, potency, and safety.

-

Clarification: The journey through downstream processing commences with the removal of solid particles, cells, and debris from the culture broth. This is a critical step that typically involves centrifugation, filtration, or other separation techniques.

-

Purification: The crown jewel of downstream processing is the purification of the target product. Chromatography techniques such as affinity chromatography, ion exchange chromatography, and size exclusion chromatography come into play to separate the target from impurities and other proteins.

-

Concentration: The purified product often faces dilution during purification. To rectify this, concentration steps, such as ultrafiltration and diafiltration, are employed to boost the product's potency.

-

Formulation: The final product may require formulation to ensure it possesses the requisite stability, dosage, and administration characteristics. This may involve fine-tuning parameters like pH, buffer composition, and the addition of excipients.

The relationship between upstream and downstream processing can be likened to a relay race, where the baton – in this case, the cultured cells or culture broth – is seamlessly passed from one phase to the next. The efficiency of upstream processing significantly impacts the ease and cost-effectiveness of downstream operations. High-yield upstream processes reduce the burden on downstream processing by providing a more concentrated and purer starting material.

Both upstream and downstream processing harbor their unique challenges, reflecting the inherent complexities of biomanufacturing.

Upstream Challenges:

-

Cell Line Development: Choosing the right cell line and optimizing its performance can be an arduous and resource-intensive endeavor.

-

Scalability: The seamless transition from small-scale laboratory bioreactors to large industrial ones can be fraught with technical challenges, necessitating extensive adjustments.

-

Contamination Risks: Maintaining aseptic conditions during cell culture is paramount to prevent contamination and safeguard product quality.

Downstream Challenges:

-

Complex Mixtures: Culture broths are a labyrinth of proteins, impurities, and contaminants, rendering purification a Herculean task.

-

Yield and Purity: Striking a balance between high yield and purity without denaturing the target product demands intricate expertise and technical finesse.

-

Cost-Effectiveness: Downstream purification processes can be resource-intensive and costly, making cost-effectiveness a perpetual goal.

Conclusions

In the bioprocessing industry, upstream and downstream processing stand as twin pillars, indispensable to the production of biopharmaceuticals and bioproducts. The efficacy of upstream processing profoundly influences the downstream journey, where purity, potency, and safety are paramount.

As biomanufacturing advances, so too will the methodologies and technologies shaping upstream and downstream processing. This perpetual evolution drives innovation and progress in the field, ensuring the continued development of high-quality, safe, and effective biopharmaceuticals for the betterment of healthcare and beyond.