How to choose the right tube for your application

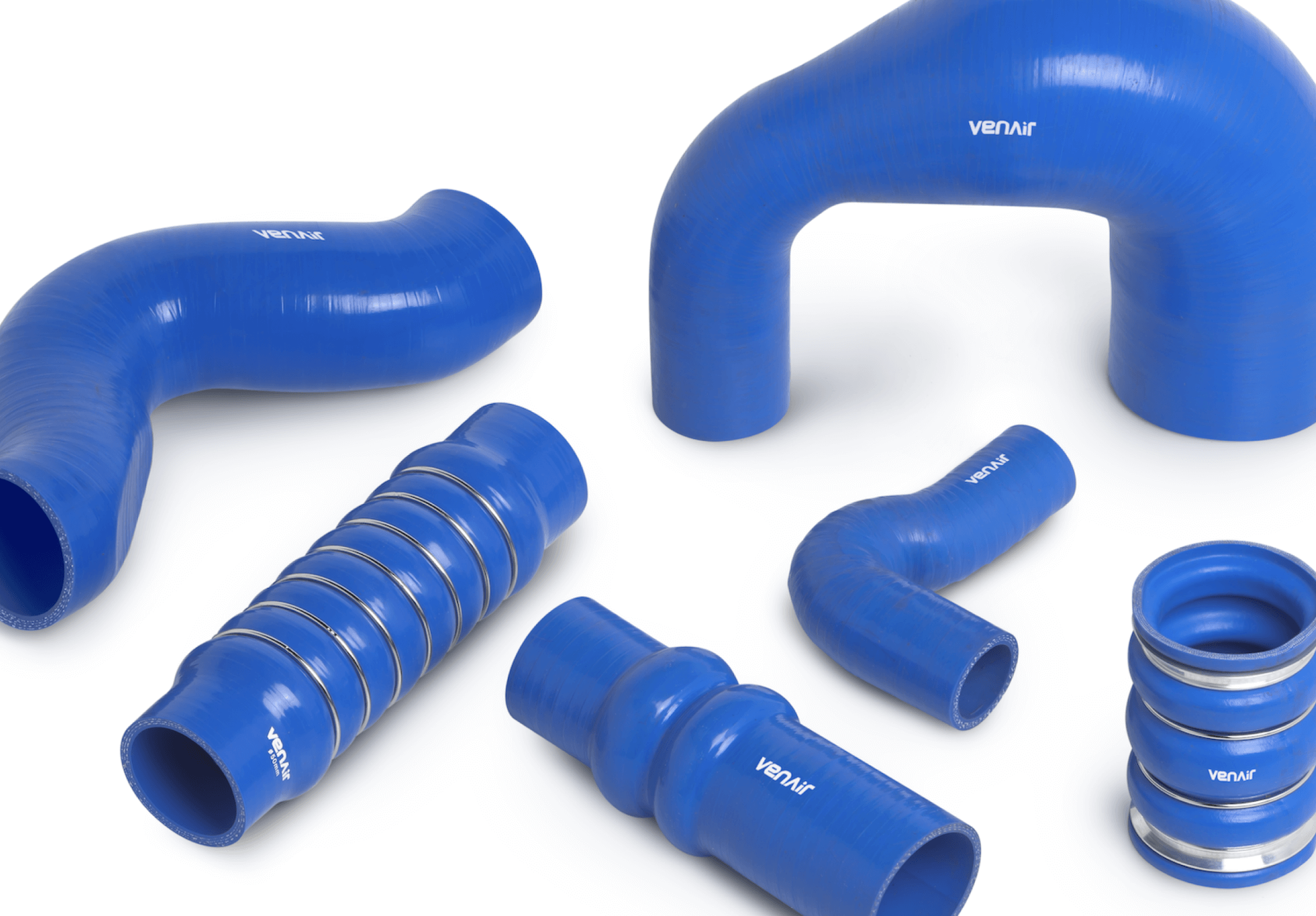

Choosing the most suitable hose for your application can be a hard decision to make because of the number of options available in our product range. For this reason, taking time in identifying and specifying your application Is key to choosing the best hose for your application.

We believe that the best way to identify the best hose for your specific application is by following the acronym S.T.A.M.P.E.D. The acronym stands for: Size, Temperature, Application, Material, Pressure, Ends and Delivery.

The S.T.A.M.P.E.D. system of hose requirements is a critical list when it comes to recommending the correct hose for the correct application. The method consists in different questions that you must answered completely and accurately.

Our specialists offer years of experience following this critical list and can help you identify and determine the best product for your operation and application.

Steps for selecting the proper hose

Size

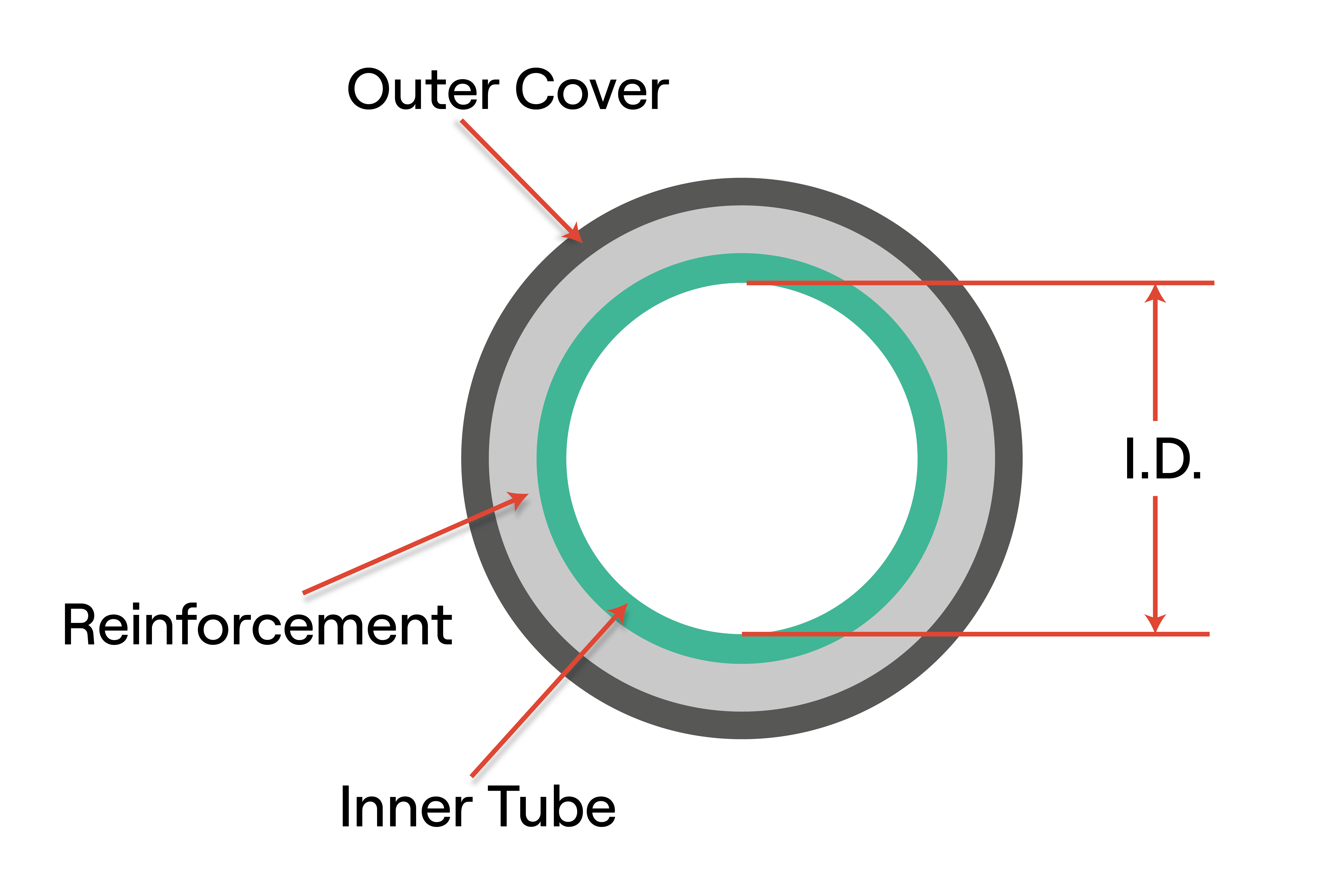

The hose must be sized accurately to obtain the most optimal flow velocity. A slow flow results in a poor system performance and a high flow creates excessive pressure drops, damages the system, and creates leaks.

The hose must be sized accurately to obtain the most optimal flow velocity. A slow flow results in a poor system performance and a high flow creates excessive pressure drops, damages the system, and creates leaks.

For this reason, it’s crucial to identify the optimal sizes of the following factors:

- Inside diameter

- Outside diameter

- Connection sizes

- Assembly length

The hose length plays an important role. You just don’t only need a hose that fits, that can be installed on your equipment. You need a hose with the proper size that don’t create failures such as twisting, kinking, or breaking.

Because of these major problems we always help you in taking the time to make sure each component of your assembly is properly selected to achieve the maximum hose-life.

Temperature

Temperature it’s also an important factor when selecting the correct hose. There are two temperatures to consider: the ambient temperature, the temperature outside of the hose, and the product temperature, the temperature of the fluid conveyed inside the hose.

Very high or low ambient temperatures can reduce the hose life. However, the product temperature presents a much greater impact on hose life; cracking, flexibility loss, drying… The product temperature can increase or decrease the effects of temperature on the hose, that’s why depending on the product it’s recommended a maximum temperature to operate.

Venair hoses are designed for being resistant to different temperature ratings for different fluids.

Also, we offer different special solutions for avoiding ambient temperature problems:

- Anti-condensation cover materials

- Telcra HT- Insulating material for high temperatures

And also, other solutions for conveying high and low media temperatures and regulate the flow temperature:

- Heated hose

- Cooling hose

Application

Before doing the selection of the hose, it’s necessary for us to understand your application. There are so many factors to consider that for this reason in Venair sometimes we believe in customization to guarantee a complete success for your equipment designs.

To identify your application needs, you should consider the following aspects:

- How did the previously installed hose perform?

- What type of equipment is involved?

- What environmental factors will the hose be exposed to?

- Will your hose operate near hazardous chemicals?

- Are mechanical loads applied to the assembly?

- Will the routing be confined?

- What about hose fittings – permanent or field attachable?

- Will the assembly be subjected to abrasion?

- What regulations might dictate what hose we’d recommend?

There are so many factors to consider so for us, the best way, is to visit your facilities and perform audits to ensure we provide you with the most appropriate solutions for your needs and requirements.

Product

What are you going to convey through the hose? The product that flows through the hose sometimes may impact the decision of the hose selection.

It’s important that the product is compatible with the hose. The inner hose, outer cover, hose-end fitting, and connections must be compatible with the product you convey.

Chemical compatibility is necessary to avoid any problem. Check our compatibility table for your application here.

Pressure

When recommending a hose for your application, we will always ask what the highest operating pressure is for your specific system or piece of equipment as well as the vacuum pressure.

It’s crucial to identify the maximum operating pressure, the frequency of pressure spikes, and if the product that you’re conveying alters the hoses pressure to select the most suitable hose.

Additionally, you also need to consider that your assemblies may need a different pressure than your hose.

Ends

Selecting the right ends; type, style, material, orientation, or attachment method to assure a proper connection is also important to prevent any leak and improve installation and operability.

In Venair we offer different fittings solutions; custom fittings, standard fittings, molded clamps… And we crimped all our hoses through a SZR system, a crimping method that assures no retention areas and guarantees safety.

Delivery

It’s also important to evaluate your delivery consideration; dates and location to determine packaging, labeling, certifications, and testing requirements. This factor can also affect the hose selection.