How often do you need to check your hoses?

Whether you’ve been working with the same hoses for a long time, or you are not sure about the operability and lifetime of the hoses installed, it’s convenient that you conduct an audit. Regular yearly audits can save you money, improve workplace safety and identify inefficiencies in your operations. Here we give you some reasons to regularly audit your hoses:

1. Saving Money

Hoses contribute to the overall performance of your application. Any problem or damage in the hose, can cause serious downtown problems that could lead to overwhelming increases in your production costs.

If your hoses haven’t been audited recently, it’s probably that some of them are not optimized for maximum operability or even, they you don’t know their lifetime to predict the right time of replacement to avoid any major problem. In order words, this ignorance could make you lose profits.

For these reasons, one of the primary goals of a hose audit is to strategically evaluate your systems, connections, and installations in order to identify areas for improvement. Even minor adjustments like adding labels or QR codes in your hoses, could help keep in track of your hose lifetime and detect the time of replacement. Or for example, improving a connection, replacing hoses with a lighter material, changing the hose with a proper length… any adjustment can help your reduce problems and operation and maintenance costs.

2. Safety is key

Without regular audits, you might be missing safety issues what could endanger your workers and facilities.

Damaged hoses, fitting failures, incorrect installations can cause a large list of safety risks. Some of these risks, may not be immediately apparent when the hose is damage. However, a professional audit can spot the risks, allowing you to replace them at the right time before the damage it’s caused.

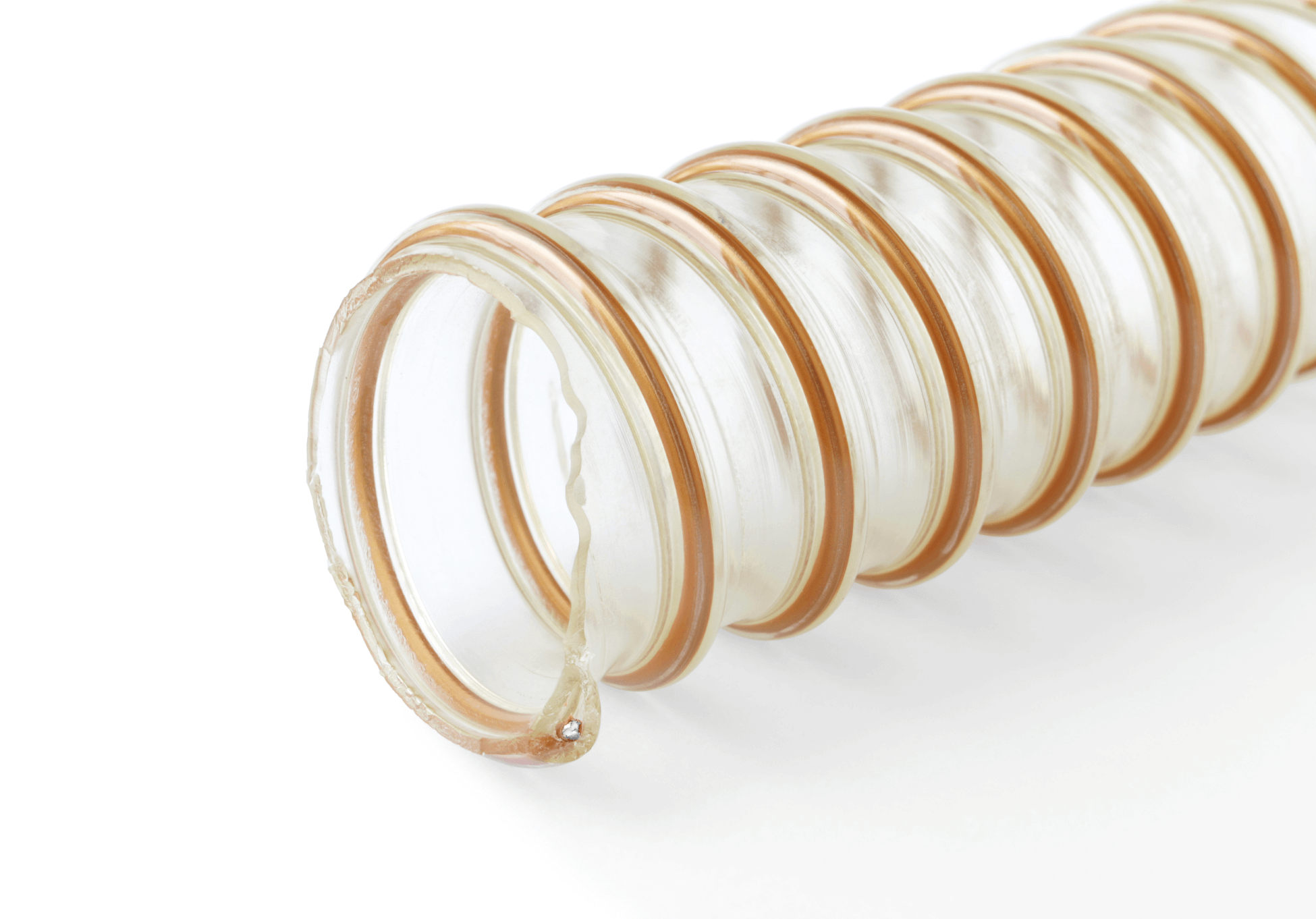

Audits can ensure that the hoses are being replace at the right time and meet the industry safety standard. However, you should be able to detect and check in a regular basis that there’s no internal or external damages like displacement of layers, displacement of wire helix from their normal pitch, signs of displacement of fittings or leakage in the ends, reinforcement fabric exposed, wire corrosion, dents, kinks, or abrasion. In these cases, it’s mandatory to replace them immediately to avoid any risk or damage.

3. There could be better solutions

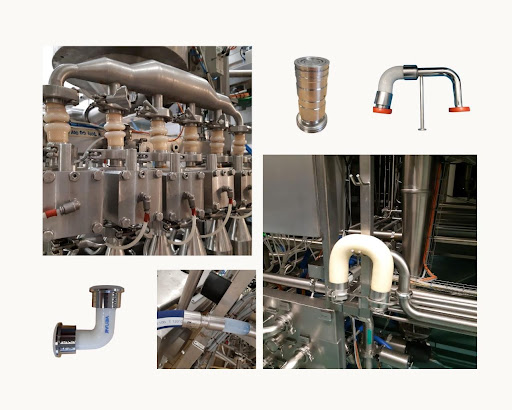

Venair offers to do audits to your installations to help you detect the status of each hose, to identify inefficiencies and safety risks. Usually, by conducting audits we help you provide better hoses that may suit your needs.

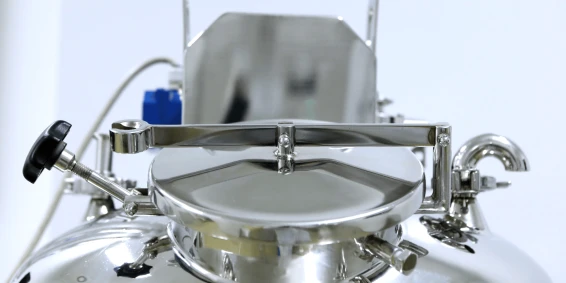

In Venair we’re capable of producing any custom solution allowing us to provide any product that can help to major problems or high requirements that you’re facing. The aim of Venair is to not only offer hoses, but complete fluid transfer systems specially designed to get the most optimal solution. Our Engineering and R&D departments work continuously in the development of new constructions like custom heated hoses, insulating covers, silicone sleeves and compensators in any length or material, resistant covers…

Additionally, we also offer different types of connections like molded clamps.

Conclusions

In conclusion, whichever hoses your organization is currently running, contact your local Venair engineer assistance for an audit at least once in a year. The engineers will provide you the best solutions that could help reduce your inefficiencies, lower your operating costs, enhance workplace safety, and ensure that you’re using the most qualitative solutions that better suit your needs.