How to measure the radius of curvature of a hose?

The minimum bending radius of a hose and the required amount of force needed to bend a hose are crucial factors in hose selection and design, specially if it will be subject to curves, strong movements, and constant stress.

What is bend radius?

The minimum bend radius refers to the minimum distance a hose can bent without damaging or shortening its life.

Most hoses must bend constantly throughout their service life, so considering flexibility requirements ahead of time saves time and money. Bending a hose more sharply than its design allows places an undue stress that can cause kinking and damage in the hose, decreasing its hose life.

Additionally, over-bending a hose can restrict flow, leading to further complications. For these reasons, it’s important to calculate in advance the minimum bend radius to determine the minimum length of hose required for a given application.

How can we calculate the bending radius?

Before calculating the bend radius, you need to answer the following questions:

- What angle of bend in degrees (A) do I need the hose to reach?

- What diameter of hose do I need?

Once, you have these answers, there’s two possible ways to calculate the minimum bend radius:

- Inside radius measures the radius of the bent hose to its innermost surface.

- Centerline radius: measures the radius to the centerline of the hose.

Centerline radius method

Centerline radius method, is the method most used, as using this formula, the minimum required length of a hose can be determined for any situation.

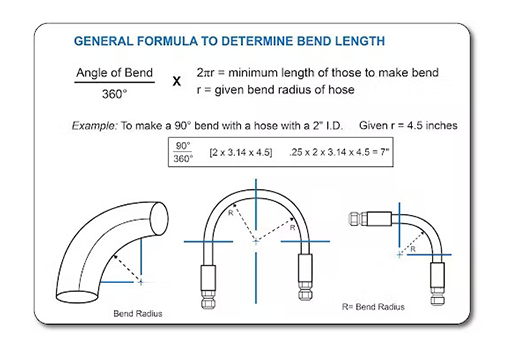

The minimum bend radius formula is:

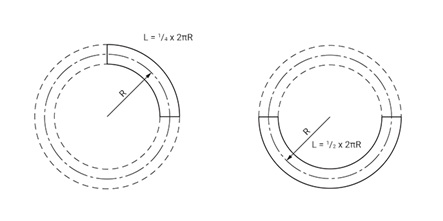

L = A/360° x 2πr.

The variables in this equation are defined as:

L: The minimum length of the hose that needs to bend

A: The angle of the bend

r: The bend radius of the hose

π: 3.14

Using this formula, the minimum required length of a hose can be determined for any situation.

When calculating the length of hose assembly, the length of the fittings must be considered.

Examples:

If a customer needs a hose that can bend at 90º and has a bend radius of three inches, then the minimum length of the hose would equal:

45º/360º x 2 (3.13) (3) = 2,3475 inches

CHANGE NUMBERS

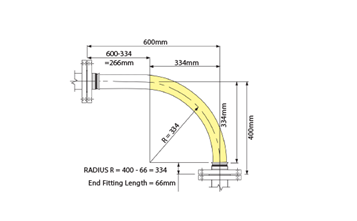

To calculate the length for a ” bore size hose with flange end fittings, to be fitted in a 90˚ configuration with one leg 400mm long, the other 600mm long.

Length of Bent Section (yellow) = 1/4 x 2πR (334) = 1/4 x 2 x 3.142 x 334 = 525mm

Length of top, Straight Section, including the top end fitting length = 600 - 334 = 266mm

Length of bottom end fitting = 66mm

Total length of Hose Assembly = 525 + 266 + 66 = 857mm

Understanding how to calculate bend radius during hose selection makes it easier to choose an appropriate length of hose. By taking the time to make these calculations upfront, you will ensure optimal functionality and service life from their hoses.

Our worldwide sales engineers will help you determine the most appropriate hose type and length for specific application.