Evolution in the Durability of Vehicles and Industrial Machinery

The durability of vehicles and industrial machinery has been a crucial aspect of the industry since its inception. Constant innovation and the development of new technologies have allowed for significant advances in this field. In this article, we will analyze how the durability of these systems has evolved and the essential role played by flexible silicone connections, with a special focus on Venair and its High Performance division.

Historical Evolution of Durability

Over the years, the durability of vehicles and industrial machinery has improved considerably. In the early stages of industrialization, the equipment was robust but lacked the efficiency and longevity we see today. The introduction of new materials and technologies has allowed manufacturers to produce machines that not only last longer but also require less maintenance.

Factors Influencing Durability

Among the factors that have contributed to the improvement of durability, the following stand out:

- Material Innovation: The development of more resistant and durable materials, such as advanced metal alloys and high-tech composites.

- Design and Manufacturing: Advances in design and manufacturing processes that allow for more precise tolerances and more robust assembly.

- Predictive Maintenance: The adoption of monitoring and analysis technologies that allow for the prediction of failures and the performance of preventive maintenance before serious problems occur.

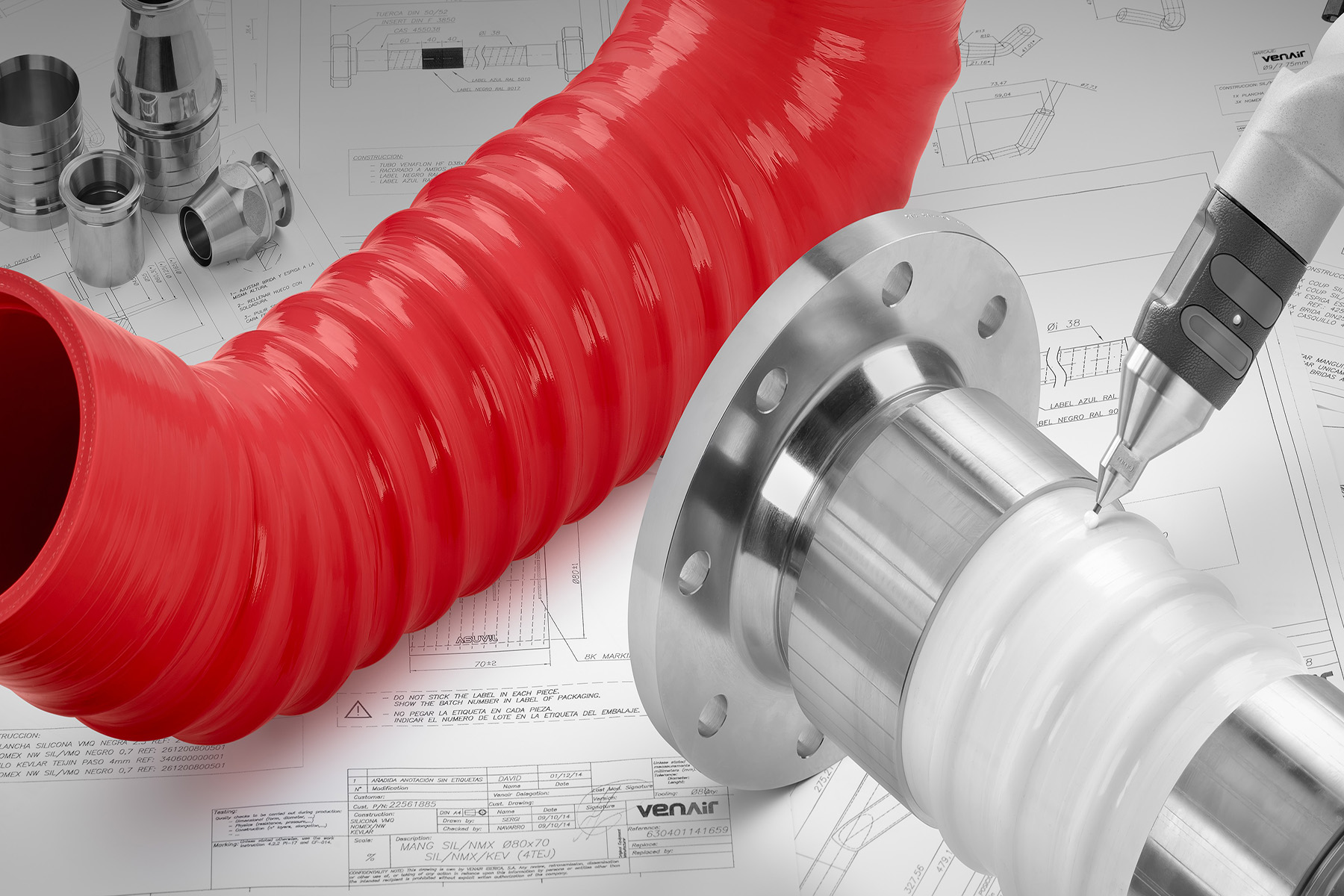

The Role of Silicone Tubes in Durability

Silicone tubes are fundamental components in numerous vehicle and industrial machinery systems. Their primary function is to act as a flexible connection between rigid metal elements, in order to absorb movements, vibrations, and design misalignments in cooling and turbo systems in industrial engines. Unlike metal parts, flexible tubes are subject to repetitive movements and vibrations that require an optimal design for correct performance while simultaneously ensuring the expected durability of the product.

Their quality and performance, therefore, have a very significant impact on the overall durability of these systems. Venair, a leader in the manufacture of silicone tubes, has been key in developing and providing solutions that withstand extreme conditions and prolong the lifespan of the equipment.

Venair and Its Contribution to Durability

Venair, recognized for its excellence in the design and manufacture of silicone tubes and other technical elastomers, offers custom-designed products to withstand the most demanding conditions in the industry. Its High Performance division is focused on the development of materials and products that not only meet the highest standards of quality but also optimize the performance and durability of the systems in which they are installed.

High Performance Solutions from Venair

Venair offers a wide range of products specifically designed for demanding industrial applications. Their silicone tubes are known for their resistance to high and low temperatures, pressure, and their optimal compatibility with the most aggressive coolant liquids on the market. These products not only improve the durability of the equipment in which they are installed but also optimize overall performance.

- Resistance to Extreme Temperatures: Venair silicone tubes can operate effectively across a wide range of temperatures, making them ideal for applications in engines and cooling systems.

- Durability and Flexibility: The combination of durability and flexibility allows Venair tubes to adapt to different configurations without compromising their structural integrity.

- Chemical Compatibility: Venair products are resistant to a wide range of chemicals, including the most aggressive coolants on the market, making them ideal not only for applications in engine cooling systems but also for other specific industrial equipment.

- Safety – Fire Resistance: A very important advantage of silicone products is their high fire resistance and low rate of emission and toxicity of fumes. Venair has developed several products certified according to railway and flammability in plastics standards, EN-45545-2, and UL-94.

- Customization: Venair offers a customized product, designed to the client’s specifications (materials, geometry, connections…) to meet all their requirements and achieve the most optimal system performance.

Success Stories with Venair

Numerous companies in the vehicle and industrial machinery sector have significantly improved the durability and performance of their equipment by incorporating Venair silicone tubes. The ability of these tubes to maintain their integrity under extreme conditions has been a decisive factor in reducing downtime and increasing operational efficiency.

Conclusion

The durability of vehicles and industrial machinery has evolved significantly thanks to innovation in materials, design, and predictive maintenance. Venair, with its High Performance silicone tubes, plays an essential role in this evolution. Their high-quality products not only improve the lifespan and performance of the equipment but also ensure that these function optimally in the most demanding conditions. As the industry continues to advance, Venair silicone tubes will remain crucial in maintaining and improving the standards of durability and efficiency.