Venair's New High-Pressure Tubing for Hydrogen Applications

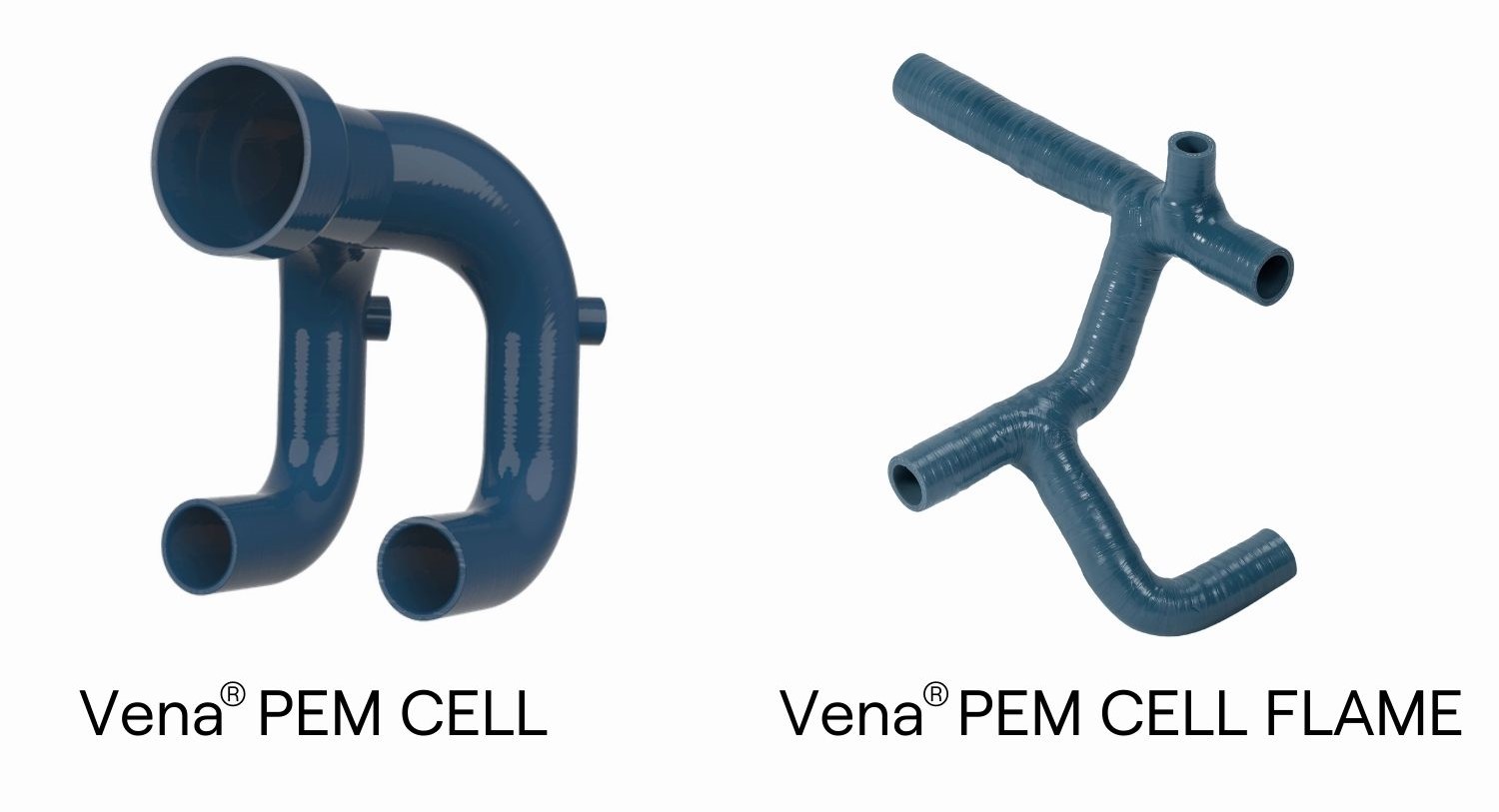

At Venair, we are continuously pushing the boundaries of material engineering to meet the demanding requirements of hydrogen-based systems. Our latest development focuses on increasing the pressure resistance of our specialized hydrogen tubes, VENA® PEM CELL FLAME and VENA® PEM FUEL, to cater to applications that operate at much higher pressures than standard fuel cells.

High Pressure Silicone Hoses for PEM electrolyzers

One such application is PEM electrolyzers, which typically operate at pressures of up to 30 bar. In these high-pressure environments, the integrity of the tubing system is critical. The safe and efficient transport of hydrogen demands that potential leaks be minimized to ensure both performance and safety.

Hydrogen's small molecular size makes it particularly challenging to contain, as it can escape through even the smallest imperfections in a system. The two primary areas where leaks can occur are at connection points and due to the permeability of materials used. This makes addressing these challenges a top priority in the development of hydrogen transport systems.

At Venair, we tackle these challenges with a twofold approach:

- Specialized Connections: We develop customized gas connections that minimize the risk of hydrogen leaks. These connections not only enhance the sealing performance but are also designed to withstand hydrogen’s unique properties, such as its ability to cause embrittlement in certain metals. Our connections are optimized for compatibility with hydrogen, ensuring durability without degradation or oxidation.

- Advanced Low-Permeability Materials: To further reduce the risk of hydrogen escaping through the tube walls, we have focused on creating and utilizing materials with extremely low permeability. These materials are engineered to resist the passage of hydrogen, while also ensuring excellent compatibility with the gas. This results in tubes that can withstand higher pressures while maintaining a strong barrier against leakage, making them ideal for high-pressure hydrogen applications.

Advanced materials in silicone hoses

Our advancements in material science and design are crucial to ensuring the reliability and efficiency of hydrogen subsystems, especially as industries look to scale up hydrogen usage for clean energy solutions. Whether for fuel cells or high-pressure systems like PEM electrolyzers, Venair's specialized hydrogen tubes provide the safety, durability, and performance that these critical systems require.

With hydrogen playing an increasingly vital role in the global energy transition, our commitment at Venair is to continue innovating and offering state-of-the-art solutions for hydrogen systems that operate at the highest standards of safety and efficiency.