Monoclonal Antibodies and Single-Use Systems in Bioprocessing

What are monoclonal antibodies?

Monoclonal antibodies (mAbs) are a type of protein that are used in the treatment of a variety of diseases. They are made by identical immune cells that are all clones of a single parent cell, hence the name "monoclonal."

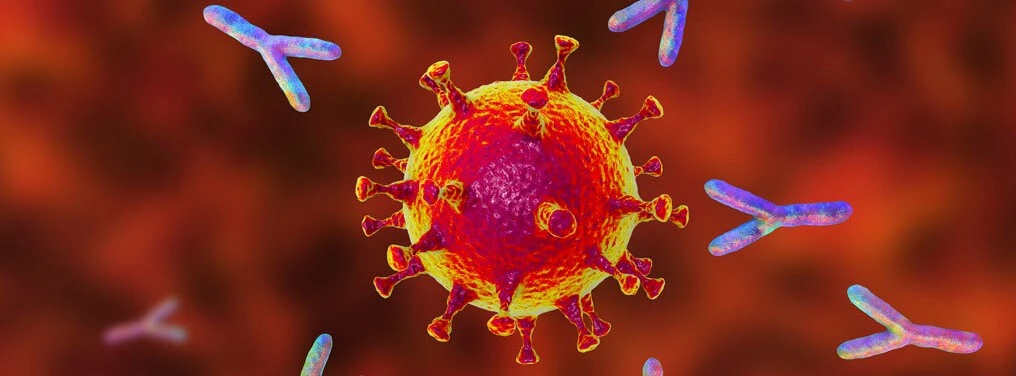

mAbs work by attaching to particular targets known as antigens (often distinct receptors found on the cell surface), with very high affinity and specificity, similar to how the immune system antibodies work.

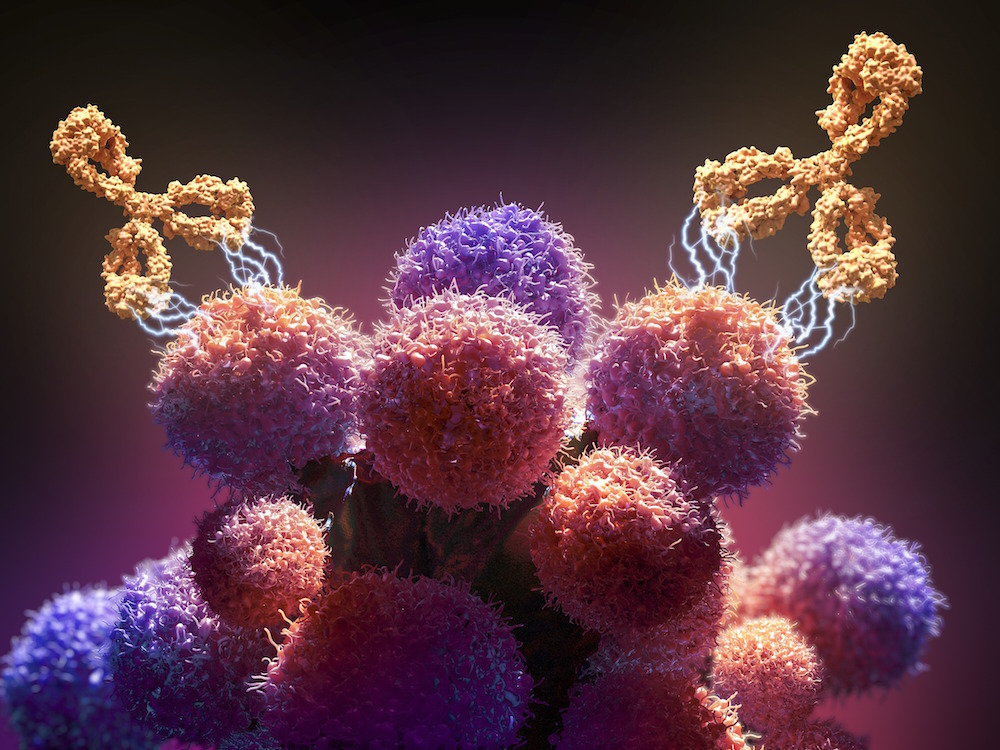

This binding can lead to a variety of effects, depending on the target and the mAb in question. For example, this may lead to tumor elimination by inhibition of essential functions of the malignant cells like the dimerization or the signal cascade propagation processes. Moreover, mAbs can also bind to target enzymes to help its elimination or even be used to deliver therapeutic molecules directly to cancer cells when conjugated with drugs.

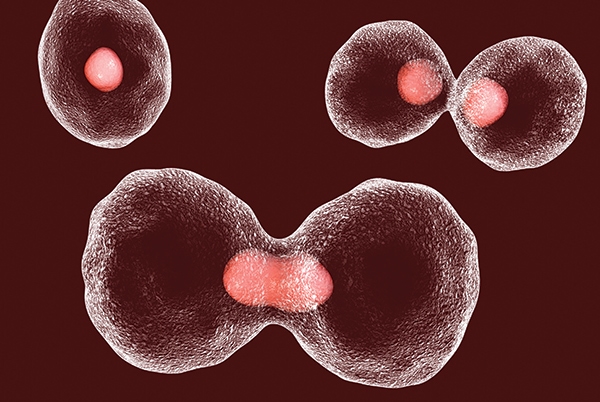

mAbs are produced by hybridoma technology, a method in which B cells, a type of white blood that produces antibodies, are harvested (usually from mouse or other mammals) and fused with immortal cancer cells called myeloma, leading to the creation of hybrid cells referred to as hybridomas. These hybridomas can be cultured similarly to regular cell lines, resulting in the development of genetically identical cell lineages with the capacity to produce a single specific antibody.

Advantages of monoclonal antibodies

The main advantage of mAbs is their high specificity, selectivity and affinity. This allows them to discriminate particular receptors and affect only malignant cells (in cancer cases) or infectious bacteria. Consequently, healthy cells and beneficial bacteria remain untouched, resulting in reduced treatment toxicity and side effects, increasing both the safety of the therapy and the overall well-being of the patient.

Another reason for the success of mAbs based therapy is that they can be engineered to modulate their properties. Like all antibodies, mAbs consist of three segments: two identical antigen-binding regions known as Fabs, and a singular highly conserved region called the Fragment crystallizable (Fc), which influences the immune response of the molecules.

By engineering the Fabs regions, it becomes possible to enhance affinity and stability, and even enable binding to diverse therapeutic targets. Meanwhile, adjustments to the Fc region allow for the fine-tuning of molecule activity, fostering the creation of innovative immunotherapeutic approaches.

Finally, mAbs have also become a valuable therapy for the treatment of viral infections and diseases by binding to viral antigens and neutralizing them or stimulating the patient immune system for their elimination.

mAbs bioprocessing production and applications.

Nowadays, mAbs are one of the fastest growing classes of biotherapeutics and have been dominating the industry for almost 30 years.

By using genetically engineered host cells, such as Chinese Hamster Ovary (CHO) cells, mAbs can be produced in large quantities in bioreactors enabling the efficient and cost-effective production of life saving drugs for the treatment of various diseases, including cancer, inflammation, and autoimmune disorders.

Besides their use as therapeutic molecules, mAbs can also be produced to serve as reagents and tools in the purification and analysis of other proteins. They can isolate specific proteins from complex mixtures, such as blood or cell lysates, by binding to the target protein and then pulling it out using techniques such as magnetic bead purification or flow cytometry. In the same sense, they are very valuable tools for the diagnostic, detection and prevention of a wide array of diseases.

Benefits of using Single-Use Systems (SUS) in Bioprocessing

Venair's High-Quality Components for Seamless Implementation

In recent years, the use of single-use systems (SUS) has become more prevalent in the bioprocessing industry, mainly due to the ease of use, cost-effectiveness, reduced cleaning and validation steps and mitigation of the contamination risk of the processes.

The flexibility of SUS also allows for easy scale-up or scale-down of processes. Silicone tubing, polyethylene bags, and other single-use components are important for the implementation of single-use systems in the production of mAbs and other bioprocessing applications.

Venair offers a variety of silicone tubing, polyethylene bags, and other single-use components that are well suited for use in the bioprocessing industry and can help companies to implement single-use systems in their manufacturing processes.

Conclusions

Overall, mAbs are a powerful tool in the fight against disease and are increasingly being used in the bioprocessing industry for the production of therapeutic proteins and as reagents in purification and analysis. With the advent of single-use systems and advancements in engineering, the production of mAbs has become more efficient and cost-effective, making these life-saving drugs more widely available to patients in need.