Why End Users Benefit from Venair’s In-House Manufacturing of Single-Use Assemblies

The Growing Importance of Single-Use Assemblies

In biopharmaceutical manufacturing, single-use assemblies are no longer optional; they are central to efficient, sterile, and scalable operations. By eliminating cleaning validation, reducing turnaround times, and minimizing contamination risks, they enable manufacturers to operate with greater flexibility and reliability. For end users, however, not all assemblies are created equal. The integrity of the entire system depends directly on the quality of its critical components.

Why Component Origin Matters

Most suppliers source tubing, bags, and connectors from different manufacturers and then assemble them into final systems. While functional, this approach creates challenges for the end user, particularly in components that come into direct contact with the process media:

- Multiple supply chains → higher risk of variability, inconsistent quality standards, and potential weak points.

- Fragmented validation → each component may come with separate testing and certificates, increasing the regulatory and documentation burden.

- Limited process control → without direct oversight of component manufacturing, reproducibility and performance assurance can vary.

For operators in GMP environments, these factors translate into additional risk, longer qualification processes, and reduced confidence in critical single-use assemblies.

Venair’s Advantage: Vertical Integration

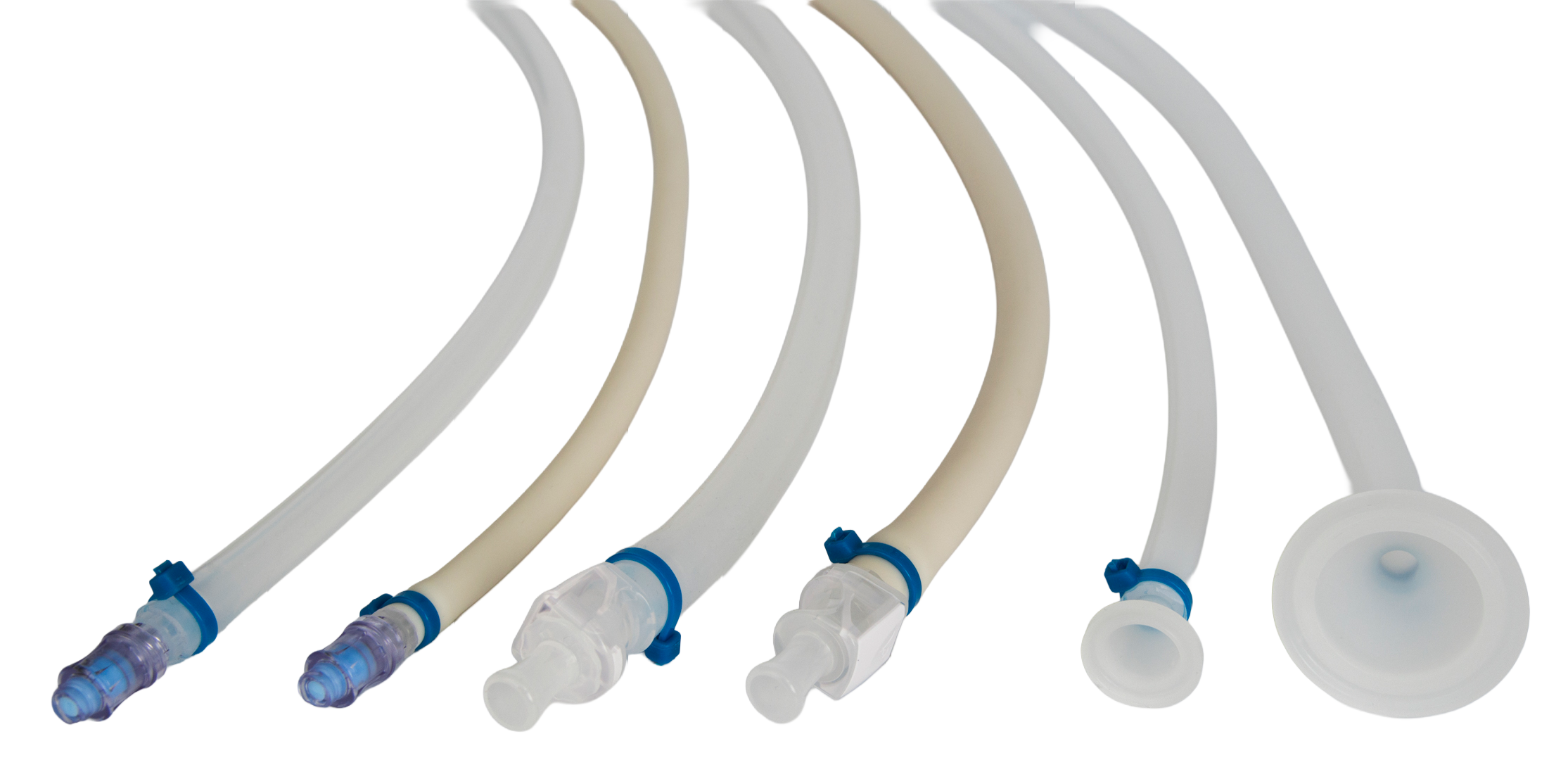

Venair takes a different approach. Beyond assembling customized single-use solutions, Venair also manufactures the most critical contact components in-house:

- Tubing (VenaBio® Flow, Flex, Braided Plus)

Produced in ISO Class 7 cleanrooms, platinum-cured silicone and TPE tubing are designed for biopharma use with ultra-low extractables, wide temperature and pressure resistance, and full validation packages. This ensures that fluid pathways are chemically inert, mechanically robust, and fully traceable. - 2D Bioprocessing Bags (VenaBio® Bag 2D)

Constructed from multilayer PE/EVOH films, these bags provide superior oxygen and moisture barrier properties, are biocompatible and animal-free, and undergo 100% leak testing before release. End users gain confidence that their media and buffers are stored and transferred under validated, secure conditions. - Customized Assemblies

Built on Venair’s own tubing and bags, the assemblies integrate seamlessly and consistently, and can be customized by combining them with other desired components when required.

End-User Perspective: Why It Matters

For biopharma manufacturers, the choice of assembly supplier is not just about technical configuration – it is about risk management and operational efficiency. Venair’s model translates into:

- Simplified qualification and regulatory compliance: fewer suppliers mean streamlined documentation and validation.

- Greater process security: assemblies and components are designed, tested, and validated under one unified quality system.

- Improved reliability: in-house production reduces variability, ensuring consistent performance across batches and sites.

Conclusion

For end users, the real value of Venair’s single-use assemblies lies in more than customization. It is the assurance that comes from working with a supplier that designs, manufactures, and validates its own critical components. This vertical integration delivers assemblies with unmatched reliability, traceability, and compliance – giving biopharmaceutical manufacturers the confidence to focus on their processes, not their risks.