Silicone Tubing vs. TPE Tubing: How to Choose the Right Solution for Bioprocesses

In biopharmaceutical manufacturing, every element of the fluid path must meet the highest requirements for safety and reliability. Tubing is a critical component in sterile transfer lines, single-use systems, and downstream operations. Two materials dominate this field: silicone and thermoplastic elastomers (TPE). Each offers specific advantages, and Venair provides tailored solutions with VenaBio® Flow (silicone tubing) and VenaBio® Flex (TPE tubing).

The role of silicone tubing

Silicone has been a trusted material in biotechnology for decades thanks to its purity, biocompatibility, and resistance to chemical interactions. VenaBio® Flow is a platinum-cured silicone tubing manufactured in ISO Class 7 cleanrooms, ensuring extremely low extractables and a complete validation package.

Another major advantage is its ability to withstand a wide temperature range, from –60 °C to +220 °C, making it suitable for diverse applications. Its flexibility reduces the risk of kinking, which is especially important in peristaltic pumping, filling, and delicate fluid transfers.

In short, silicone stands out for its purity and durability, being the preferred choice when product integrity is the top priority.

The value of TPE tubing

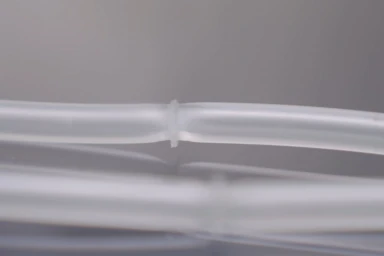

Thermoplastic elastomers have gained relevance, particularly in single-use systems. Their main advantage is the ability to be welded and thermally sealed, enabling closed, secure, and sterile connections essential in aseptic environments.

VenaBio® Flex has been designed with these needs in mind. It is biocompatible, free of plasticizers and additives, performs well in peristaltic pumps, and is stable under gamma sterilization.

Moreover, it can be welded not only with itself but also with other TPE brands, making it a highly versatile option for integration into different assemblies. This capability provides great flexibility in process design and simplifies the creation of sterile fluid paths in mixed configurations.

Conclusion

Both silicone and TPE offer excellent performance in bioprocesses, but each material excels in different areas. Silicone provides purity, durability, and thermal resistance, while TPE offers weldability, aseptic connections, and compatibility with sterilization methods. With VenaBio® Flow and VenaBio® Flex, Venair delivers reliable solutions designed to ensure process safety, product integrity, and smooth integration into modern bioprocessing systems.